Tinplate coils deliver unmatched durability, corrosion resistance, and sustainability in the tinplate for packaging market. Witop’s Lattine Banda Stagnata tinplate coil meets global standards and adapts to a wide range of packaging demands. The tinplate industry values these coils for their strength and formability. Manufacturers rely on tinplate for packaging market solutions that offer both environmental sustainability and product safety. A closer look at the tinplate industry shows that tinplate coils achieve infinite recyclability and high recycled steel content, making them essential for sustainable packaging.

Tinplate coils deliver unmatched durability, corrosion resistance, and sustainability in the tinplate for packaging market. Witop’s Lattine Banda Stagnata tinplate coil meets global standards and adapts to a wide range of packaging demands. The tinplate industry values these coils for their strength and formability. Manufacturers rely on tinplate for packaging market solutions that offer both environmental sustainability and product safety. A closer look at the tinplate industry shows that tinplate coils achieve infinite recyclability and high recycled steel content, making them essential for sustainable packaging.

Thickness (mm) Tin Coating (microns) Tin Weight (g/m²) Hardness Grades Sustainability 0.12–0.60 2.0–8.4 1.1–8.4 T1–DR9 Infinite recyclability, ISO 14001 compliance

Choosing tinplate for packaging market applications means choosing long-term performance and sustainability.

Key Takeaways

- Tinplate coils offer strong durability and protect packaging from dents, corrosion, and damage during transport and storage.

- The tin coating prevents rust and moisture from reaching the steel core, extending the shelf life of packaged goods.

- Tinplate coils are 100% recyclable and support sustainable packaging through closed-loop recycling systems.

- Manufacturers can customize tinplate coils by grade, thickness, coating, and finish to meet specific packaging needs.

- Tinplate packaging meets strict international safety and quality standards, ensuring product protection and consumer safety.

- Tinplate coils are versatile, used in food cans, industrial containers, cosmetics, and consumer goods packaging.

- Advanced coatings on tinplate coils are non-toxic, BPA-free, and maintain food safety even under harsh conditions.

- Market trends favor lightweight, smart, and customizable tinplate packaging that meets growing consumer demand for eco-friendly solutions.

Tinplate Coil Advantages

Durability

Physical Strength

Tinplate coils deliver exceptional physical strength, making them a preferred choice in the tinplate for packaging market. The tinplate industry relies on the robust structure of tinplate coils to ensure that packaging maintains its integrity during transport, storage, and handling. Manufacturers select tinplate for packaging market applications because the material resists dents, deformation, and impact. This strength supports the production of cans that protect contents from external forces, preserving both quality and safety. The tinplate coil’s cold-rolled steel core provides a solid foundation, while the tin coating enhances mechanical performance. As a result, tinplate coils meet the demanding requirements of the tinplate packaging market, where reliability and product protection are essential.

Longevity

Longevity is a hallmark of tinplate coils in the tinplate packaging market. The tinplate industry values materials that extend the shelf life of packaged goods. Tinplate coils offer long-term durability, ensuring that packaging remains effective over time. The combination of steel and tin creates a barrier that withstands years of use without significant degradation. This durability is especially important for food cans, beverage cans, and industrial containers, where extended storage is common. The tinplate for packaging market benefits from the ability of tinplate coils to maintain their protective properties, even under challenging conditions. Manufacturers trust tinplate coils to deliver consistent performance, reducing the risk of spoilage or contamination.

Corrosion Resistance

Tin Coating

The tin coating on tinplate coils serves as a critical defense against corrosion. In the tinplate packaging market, this feature ensures that packaging resists rust and contamination.

The tinplate industry recognizes that the tin layer acts as a protective shield, preventing oxygen and moisture from reaching the steel core. This barrier is essential for cans used in food, beverages, and chemicals. The tinplate for packaging market depends on this property to keep products safe and fresh.

The uniformity and microstructure of the tin coating influence ductility, adhesion, and overall corrosion behavior. Manufacturers maintain strict control over the electrolytic tin plating process to avoid defects and ensure consistent quality. Real-time monitoring and optimized process parameters help tinplate coils retain their corrosion resistance across various environmental conditions.

- Tinplate coils withstand transport, storage, and sterilization without compromising contents.

- The tin coating prevents oxygen and moisture ingress, extending shelf life.

- Tinplate packaging resists sterilization processes, making it suitable for ready-to-eat meals.

- Tinplate coils protect food, chemicals, and industrial substances from corrosion and contamination.

Moisture Protection

Moisture protection is a key advantage of tinplate coils in the tinplate packaging market. The tinplate industry relies on the impermeable nature of tinplate to safeguard products from humidity and water vapor. This feature is vital for packaging sensitive goods, such as food and pharmaceuticals. Tinplate coils prevent moisture from penetrating cans, reducing the risk of spoilage and maintaining product quality. The tinplate for packaging market values this property for its role in extending shelf life and ensuring consumer safety. Tinplate packaging also supports the storage of chemicals and oils, where moisture resistance is crucial for health and pollution prevention.

Solderability

Manufacturing Ease

Tinplate coils offer excellent solderability, streamlining the manufacturing process in the tinplate packaging market. The tinplate industry benefits from the ease with which tinplate can be joined, shaped, and formed into various packaging solutions. The tin coating facilitates smooth soldering, allowing manufacturers to produce cans with strong, leak-proof seams. This property reduces production time and enhances efficiency. Tinplate coils support a wide range of forming operations, from deep drawing to stamping, making them versatile for different packaging needs. The tinplate for packaging market values this adaptability, as it enables the creation of custom shapes and sizes for diverse applications.

Sealing Quality

Sealing quality is another strength of tinplate coils in the tinplate packaging market. The tinplate industry prioritizes packaging that maintains a secure seal to protect contents from external contaminants. Tinplate coils enable the production of cans with tight, reliable closures. The superior solderability of tinplate ensures that seams remain intact, preventing leaks and preserving freshness. This feature is especially important for food and beverage cans, where product integrity is paramount. The tinplate for packaging market depends on the consistent sealing performance of tinplate coils to meet safety and quality standards.

Note: Tinplate coils are available in a variety of grades, tempers, and finishes, supporting customization for specific packaging requirements. The following table highlights some of the options available for industrial packaging:

| Specification | Details |

|---|---|

| Material Grades | SPCC, MR |

| Tempers | T1, T2, T3, T4, T5, DR8, DR9 |

| Tin Coating | 1.1 to 11.2 g/m² |

| Thickness | 0.15 to 0.70 mm (±0.01 mm tolerance) |

| Surface Finishes | Bright, stone, silver, matte, gold lacquered |

| Customization | Temper, finish, coating weight, and size |

The tinplate for packaging market benefits from these customization options, enabling manufacturers to tailor tinplate coils for specific applications, whether for food cans, industrial containers, or specialty packaging.

Compliance

International Standards

Tinplate coils in the tinplate packaging market must meet rigorous international standards to ensure consistent quality and safety. Manufacturers rely on standards such as JIS G 3303, ASTM A623M, and DIN EN 10203 to guarantee that tinplate coils deliver reliable performance in demanding packaging environments. These standards define the composition, coating thickness, and mechanical properties of tinplate, supporting the tinplate for packaging market with products that maintain uniformity and durability.

The tinplate industry recognizes that compliance with these standards is essential for packaging applications, especially for food and beverage cans. Consistent mechanical and surface properties help tinplate coils resist corrosion and maintain strength during transport and storage. The tinplate packaging market benefits from strict adherence to these benchmarks, which protect consumer health and product integrity.

Manufacturers also follow ISO 9001 for quality management and HACCP for food safety controls. These systems ensure that tinplate coils meet the highest standards for hygiene and reliability. The tinplate for packaging market depends on these certifications to maintain trust and meet regulatory requirements.

Note: International standards support the tinplate packaging market by providing technical guidelines for composition, coating, and performance. This ensures that tinplate coils remain safe and effective for packaging sensitive goods.

| Standard | Scope/Focus | How It Ensures Quality and Safety |

|---|---|---|

| JIS G 3303 | Composition, coating thickness, mechanical properties | Ensures consistent mechanical and surface properties, enhancing durability and safety |

| ASTM A623M | Steel base composition, tin plating amount, tempering, corrosion resistance, mechanical performance | Provides detailed testing methods and technical indicators to maintain high product standards and safety |

| DIN EN 10203 | Composition and mechanical properties of tinplate | Guarantees product uniformity and performance in various applications |

| ISO 9001 | Quality management system | Guarantees consistent manufacturing quality and process control |

| HACCP | Hazard analysis and critical control points | Implements preventive controls to reduce contamination risk and ensure food safety |

Safety

Safety remains a top priority in the tinplate packaging market. Tinplate coils must protect contents from contamination and preserve product quality. Manufacturers use tinplate for packaging market solutions that comply with food safety management systems such as Codex Alimentarius, HACCP, and ISO 22000. These systems prevent contamination and ensure hygiene throughout the production process.

Tinplate coils offer non-toxic surfaces and resist chemical reactions, making them ideal for packaging food, beverages, and sensitive industrial products. The tinplate industry values the ability of tinplate coils to maintain product safety during long-term storage and transport. Cans made from tinplate coils provide secure barriers against moisture, oxygen, and external pollutants.

The tinplate for packaging market relies on these safety features to meet consumer expectations and regulatory standards. Manufacturers implement continuous improvement and preventive controls to guarantee that tinplate coils deliver reliable protection in every application. The tinplate packaging market benefits from the assurance that tinplate coils support both product integrity and consumer health.

Tinplate coils in the tinplate packaging market must meet strict safety requirements. These requirements include non-toxic surfaces, corrosion resistance, and compliance with food safety standards. Manufacturers trust tinplate coils to deliver safe packaging for a wide range of products, including food, beverages, chemicals, and cosmetics.

Packaging Applications

Tinplate coils play a vital role in the tinplate for packaging market, offering unmatched versatility for packaging across multiple sectors. Manufacturers rely on tinplate coils to produce cans in a wide range of shapes and sizes, meeting the demands of food and beverage packaging, industrial containers, and consumer goods. The tinplate packaging market values the adaptability of tinplate coils, which can be customized for thickness, coating, and steel grade to optimize performance for each application.

Food Cans

The food and beverage packaging sector depends on tinplate coils for reliable protection and extended shelf life. Cans made from tinplate coils provide a strong barrier against oxygen, moisture, and light, preserving the freshness and quality of products.

Juice

Juice packaging requires cans that maintain flavor and prevent spoilage. Tinplate coils deliver airtight seals and moisture resistance, keeping juice safe during transport and storage. The tinplate for packaging market recognizes the importance of these features for food packaging.

Soft Drinks

Beverage cans for soft drinks benefit from the corrosion resistance and formability of tinplate coils. The tinplate packaging market uses these cans to protect carbonation and taste, ensuring consumers receive high-quality beverages.

Coffee & Tea

Coffee and tea packaging relies on tinplate coils for light resistance and secure sealing. These cans block external contaminants and preserve aroma, supporting the food and beverage industry’s commitment to product integrity.

Tinplate coils provide effective sealing and storage protection for food cans. The uniform tin plating layer ensures strong welding seals suitable for automated canning, contributing to reliable sealing and storage protection.

Industrial Containers

Industrial packaging applications require materials that withstand harsh environments. Tinplate coils offer the strength and chemical resistance needed for storing chemicals and oils.

Chemicals

Chemical packaging demands leak-proof containers with superior corrosion resistance. Tinplate coils combine steel’s strength with tin’s protective qualities, making them ideal for storing paints, solvents, and other industrial chemicals. The tinplate for packaging market values these properties for safety and durability.

Oils

Oil packaging benefits from the malleability and moisture resistance of tinplate coils. Manufacturers produce cans in various shapes and sizes, ensuring secure storage and transport of oils. Surface treatments enhance chemical resistance, supporting the tinplate packaging market’s focus on long-lasting containers.

- Tinplate coils provide superior corrosion resistance, protecting contents from leaks and contamination.

- Surface treatments like coatings or lacquers can enhance chemical resistance further.

Consumer Goods

The tinplate for packaging market extends beyond food and beverage packaging to include consumer goods. Tinplate coils support packaging for cosmetics and multi-purpose buckets, offering both aesthetic appeal and functional protection.

Cosmetics

Cosmetic packaging requires hygienic, chemically neutral containers. Tinplate coils deliver these qualities, maintaining product stability and quality. The tinplate packaging market uses tinplate for creams, lotions, and powders, ensuring safe and attractive packaging.

Multi-Purpose Buckets

Multi-purpose buckets made from tinplate coils serve various industries. These cans offer strong mechanical strength and light resistance, protecting contents from damage and contamination. The tinplate for packaging market values the recyclability and durability of tinplate coils for these applications.

| Application Sector | Packaging Examples | Key Properties Demonstrated |

|---|---|---|

| Food and Beverage | Canned foods, beverage cans | Corrosion resistance, tight seals, complex shapes |

| Industrial Packaging | Paint, chemical, oil containers | Customizable thickness, malleability, durability |

| Consumer Goods | Cosmetic jars, multi-purpose buckets | Hygienic, stable, light-resistant |

Tinplate coils continue to drive innovation in the tinplate packaging market, supporting food and beverage packaging, industrial containers, and consumer goods with reliable performance and flexible design.

Sustainable Packaging

Sustainable packaging solutions have become essential for manufacturers seeking to address environmental concerns and meet consumer expectations. Tinplate coils offer a unique combination of recyclability, non-toxic properties, and decorative appeal, making them a leading choice for eco-friendly packaging. Companies continue to invest in environmental responsibility initiatives and circular economy principles to ensure that packaging remains both functional and sustainable.

Recyclability

Closed-Loop Process

Tinplate coils support closed-loop recycling systems, which help maintain high recyclability rates across the packaging industry. Manufacturers collect used tinplate packaging, process it, and reintroduce the material into new products. This cycle conserves resources and reduces landfill waste. The steel and tin composition of tinplate enables repeated recycling without loss of quality, supporting circular economy principles and sustainable packaging solutions.

Tinplate packaging achieves high recyclability rates, with many regions reporting recovery rates above 80%. This closed-loop process ensures that tinplate remains a preferred material for sustainable packaging.

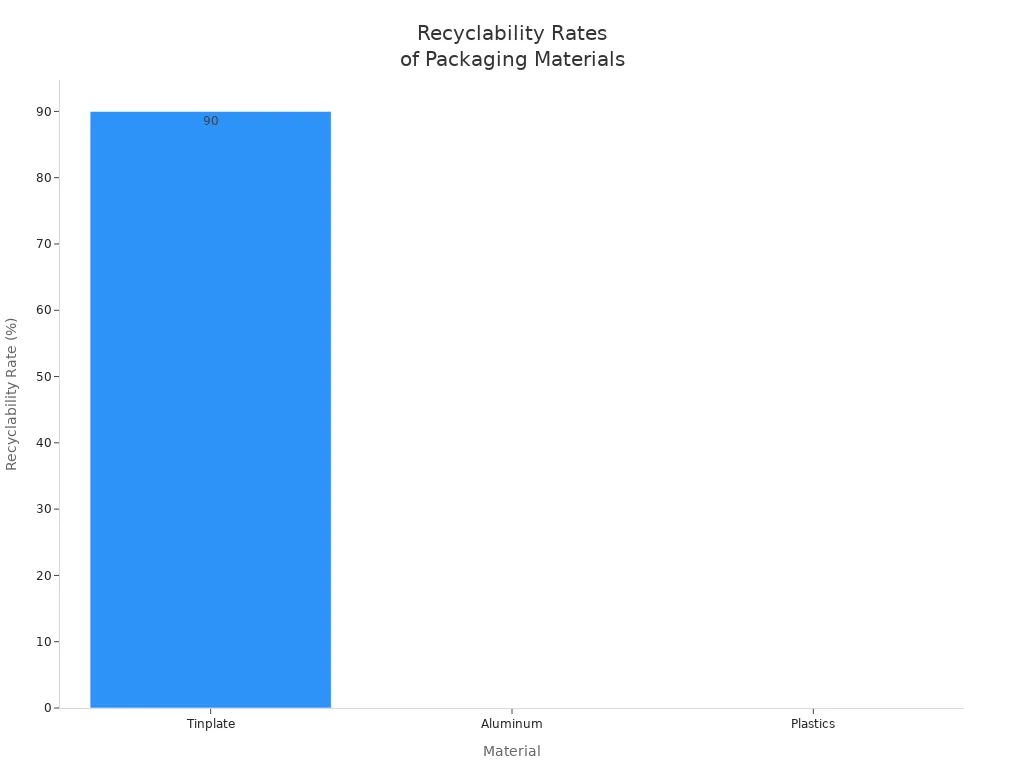

Industry Rates

The packaging sector relies on tinplate coils for their high recyclability rates. Industry data shows that tinplate packaging consistently outperforms alternatives such as plastics and paper in terms of material recovery and reuse. Innovations in manufacturing, such as the use of insoluble anodes and eco pickled surface processes, further enhance recyclability by improving product quality and reducing waste. These advancements contribute to sustainable packaging solutions and help manufacturers meet environmental concerns.

| Material | Recyclability Rate (%) | Circular Economy Contribution |

|---|---|---|

| Tinplate | 80–90 | Closed-loop, infinite cycles |

| Aluminum | 65–75 | High, but energy-intensive |

| Plastics | 10–30 | Limited, often downcycled |

Environmental Impact

Non-Toxic

Tinplate coils provide non-toxic surfaces, making them ideal for sustainable packaging solutions in food and beverage applications. The coatings used in tinplate packaging are BPA-non-intent polyester-phenol blends, designed to replace BPA-based epoxy resins. These coatings meet FDA standards and maintain chemical safety, even after sterilization. Advanced analytical techniques confirm the durability and stability of these coatings, ensuring that packaging remains safe for consumers.

- Tinplate packaging uses FDA-conform coatings that contain no harmful carbonyl or carboxylic components.

- The coatings maintain their protective properties under high temperatures and acidic conditions.

- Regulatory compliance and chemical characterization support the non-toxic nature of tinplate coils.

Resource Efficiency

Manufacturers prioritize resource efficiency in tinplate coil production to support sustainable packaging solutions. Companies implement advanced energy-efficient equipment and green technologies, reducing energy consumption and greenhouse gas emissions. Water conservation measures, such as innovative water treatment technologies, further minimize environmental impact. Product innovation and resource optimization drive sustainability, with lightweight tinplate cans reducing raw material usage and transportation costs.

A meta-review of life cycle assessment studies highlights that the choice of material and packaging mass have a greater influence on environmental impact than recyclability alone. Tinplate packaging benefits from ongoing innovations that reduce resource depletion and improve sustainability.

The development of lightweight tinplate cans and the use of recycled materials reflect significant improvements in resource efficiency, supporting environmentally responsible products and sustainable packaging.

Eco-Friendly Coatings

BPA-Free

BPA-free coatings on tinplate coils enhance food safety and environmental sustainability. These coatings create a non-reactive, food-safe surface that prevents contamination and chemical interactions. Manufacturers use low VOC, BPA-free formulations to reduce harmful emissions and comply with FDA regulations. The coatings provide long-lasting protection, even under harsh conditions, and support sustainable packaging solutions by maintaining food purity and safety.

Tinplate packaging offers excellent corrosion resistance and acts as an effective barrier against light, air, and moisture. The airtight seal preserves food freshness and safety, while the 100% recyclability of tinplate supports eco-friendly packaging and sustainability goals.

Decorative Appeal

Tinplate coils deliver decorative appeal that elevates product branding and supports sustainable packaging solutions. Advanced printing technologies produce vibrant, intricate designs that attract consumers and reinforce brand identity. Customization options, such as embossing and digital printing, allow brands to create memorable packaging experiences.

An industry expert notes that tinplate containers often serve as reusable storage, extending brand visibility and supporting sustainability. The decorative charm of tinplate packaging appeals to eco-conscious consumers, combining durability, aesthetics, and environmental responsibility initiatives.

| Eco-Friendly Coating Type | Description | Contribution to Sustainable Packaging |

|---|---|---|

| Water-Based & Solvent-Free | Avoids solvents, reduces emissions | Supports sustainability, improves aesthetics |

| UV-Curable Inks | Cures instantly, no solvent drying | Lowers VOCs, enhances durability and appeal |

| Multi-Polymer | Combines polymers, BPA-free | Extends lifespan, ensures food safety |

Tinplate packaging combines high recyclability rates, non-toxic coatings, and decorative appeal to deliver sustainable packaging solutions that meet modern environmental concerns and consumer preferences.

Comparison

Selecting the right material for industrial packaging requires a careful evaluation of cost, performance, and sustainability. Tinplate coils, aluminum, plastics, and other metals each offer unique advantages and limitations. Understanding these differences helps manufacturers align their choices with current industry trends and environmental concerns.

Aluminum

Cost

Tinplate packaging stands out as a cost-effective solution, especially for bulk storage and heavy-duty applications. Tinplate’s lower material cost appeals to manufacturers seeking economical options. However, its heavier weight can increase transportation expenses. Aluminum, while more expensive upfront, offers savings in logistics due to its lightweight nature. This makes aluminum attractive for consumer goods and long-distance shipping.

| Aspect | Tinplate Packaging | Aluminum Packaging |

|---|---|---|

| Material Cost | More cost-effective for bulk storage | Higher initial cost |

| Weight | Heavier, increases transportation costs | Lighter, reduces shipping expenses |

| Transportation Cost | Higher due to weight | Lower due to lightness |

| Durability | Excels in heavy-duty shipments | Good corrosion resistance, versatile |

| Sustainability | Highly recyclable, supports circular economy | Infinitely recyclable, energy-intensive |

Performance

Tinplate coils deliver superior durability and corrosion resistance. The steel core resists denting and puncturing, while the tin coating prevents rust and oxidation. This combination ensures long-term protection for packaged goods. Aluminum, though lighter, is more prone to dents and punctures. Its corrosion resistance is lower, making it less suitable for products requiring extended shelf life or robust sealing.

| Aspect | Tinplate Coils (Electrolytic Tinplate) | Aluminum |

|---|---|---|

| Durability | High strength, resists denting and puncturing | Lighter, more prone to damage |

| Corrosion Resistance | Excellent, prevents rust and oxidation | Less resistant, vulnerable to oxidation |

| Sealing Quality | Airtight seals, preserves freshness | Less effective barrier |

| Food Safety | Meets strict standards, no harmful leaching | May not meet all certifications |

| Recyclability | Highly recyclable, low carbon footprint | Recyclable, higher energy use |

Plastics

Environmental Impact

Plastic packaging presents significant environmental concerns. Global plastic production exceeds 400 million tons annually, but recycling rates remain low. Most plastics end up in landfills or oceans, where they degrade into microplastics and harm ecosystems. Plastics are fossil fuel-based, contributing to climate change. In contrast, tinplate coils are 100% recyclable and support circular economy goals. Steel packaging reduces energy loss and lessens the demand for paper and plastic, helping conserve natural resources.

- Plastic pollution damages marine and terrestrial environments.

- Tinplate and steel packaging align with sustainability trends and regulatory policies.

Protection

Tinplate provides a superior barrier against moisture, light, and oxygen. This protection preserves the nutritional value and safety of packaged goods. Plastics, while lightweight and versatile, often fail to prevent contamination and can leach chemicals, especially under heat or sunlight. Tinplate’s airtight seal extends shelf life and maintains product quality, making it a more reliable choice for sensitive contents.

Tinplate packaging maintains vitamin content and prevents oxidation better than plastics, ensuring food safety and freshness.

Other Metals

Weight

Tinplate, made from low-carbon steel coated with tin, is heavier than aluminum. This weight adds to transportation costs but contributes to its strength and stability. Aluminum, at about one-third the weight of tinplate, is easier to handle and ship but sacrifices some durability.

| Metal Type | Weight Characteristics | Durability Characteristics |

|---|---|---|

| Tinplate | Heavier than aluminum | Strong, corrosion-resistant, ductile |

| Aluminum | Lightweight | Weaker, less durable |

Durability

Tinplate excels in durability, offering excellent ductility and drawability. It resists corrosion and maintains structural integrity during transport and storage. Other metals, such as aluminum, provide less strength and are more susceptible to damage. Manufacturers choose tinplate for packaging applications that demand long-lasting protection and reliability.

Tinplate’s combination of weight and durability makes it ideal for industrial packaging where product safety and longevity are priorities.

Market Trends

The tinplate coil industry is experiencing rapid change, with market trends shaping the future of industrial packaging. Manufacturers and brands are responding to technological innovations, regulatory shifts, and evolving consumer demand for sustainable packaging. These factors drive the adoption of innovative packaging solutions and influence the future outlook for tinplate products.

2025 Trends

Lightweighting

Lightweighting stands out among emerging trends in tinplate production. Producers now offer tinplate coils in thicknesses below 0.15mm, reducing material use by up to 20% while maintaining durability. This approach supports efficient packaging and lowers transportation costs. The market trends indicate that lightweight tinplate packaging appeals to sectors such as food, beverage, and cosmetics, where cost savings and sustainability matter. The global tinplate packaging market is projected to reach USD 1.97 billion in 2025, expanding to USD 3.11 billion by 2034. This growth highlights the importance of lightweighting as a key strategy for future success.

Smart Packaging

Smart packaging is transforming the market trends for tinplate coils. Automation and workflow integration equipment, such as those showcased by Tension Packaging & Automation, improve production efficiency and quality control. Advanced coatings, including PVC- and bisphenol-free options, enhance safety and regulatory compliance. Manufacturers use digital printing and interactive elements like QR codes to create packaging that engages consumers and provides product information. These technological innovations align with the future outlook for smarter, more sustainable packaging.

Customization

Branding

Customization is a driving force in market trends for tinplate packaging. Advances in lacquering and digital printing allow brands to create vibrant, high-resolution designs. Heineken’s limited-edition tinplate cans with seasonal graphics led to a 31% sales increase in 2023. Tinplate’s malleability enables diverse shapes and sizes, supporting luxury cosmetics and pharmaceuticals where aesthetics and protection are crucial. Custom packaging enhances brand recognition and consumer appeal, turning packaging into a powerful marketing tool.

- Custom tinplate packaging aligns with brand identity and helps products stand out.

- Flexibility in design allows intricate patterns, vibrant colors, and unique finishes.

- Embossing and debossing add texture, improving tactile experience and brand identity.

Design Flexibility

Design flexibility remains central to market trends. Tinplate supports innovative packaging solutions with exceptional printability and protective coatings. Brands use matte, glossy, and textured finishes to match their visual identity. Interactive features, such as augmented reality markers, foster consumer engagement. These options elevate shelf presence and support the future outlook for premium packaging.

Regulatory Drivers

Safety Standards

Regulatory drivers play a significant role in shaping market trends. European regulations enforce strict food safety standards and environmental directives. Producers must comply with Extended Producer Responsibility schemes, recycled content mandates, and material restrictions like RoHS. Automation and advanced monitoring systems help manufacturers meet safety and environmental requirements. Enhanced corrosion resistance and advanced coatings improve product safety and durability.

| Regulatory Driver | Impact on Tinplate Packaging |

|---|---|

| Food Safety Standards | Prevent contamination, ensure hygiene |

| EPR Schemes | Incentivize recyclable designs |

| Recycled Content Mandates | Promote use of recycled materials |

| Plastic Taxes | Encourage sustainable alternatives |

| Carbon Pricing | Lower carbon footprint in production |

Consumer Demand

Consumer demand for sustainable packaging continues to influence market trends. Countries such as China, India, and the US show rising demand for eco-friendly packaging in food, beverage, and automotive sectors. European nations increase adoption of recyclable tinplate solutions. Urbanization and health-conscious lifestyles boost demand for packaged goods, especially ready-to-eat meals. Tinplate’s recyclability and durability meet consumer preferences for sustainable products, supporting brand loyalty and market expansion.

- The global tinplate packaging market expands as consumers shift toward eco-friendly products.

- Tinplate recycling rates exceed 80%, supporting sustainability goals.

- Transitioning from plastic to tinplate packaging helps brands reduce waste and carbon footprint.

The future outlook for tinplate coils in industrial packaging remains strong, driven by market trends in lightweighting, smart packaging, customization, and regulatory compliance. Manufacturers who embrace these innovative packaging solutions will meet evolving consumer demand for sustainable packaging and secure their position in the market.

Tinplate coils deliver outstanding durability, corrosion resistance, and sustainability, making them a top choice for sustainable packaging. Witop’s Lattine Banda Stagnata tinplate coil stands out for its versatility and reliability across food, beverage, and industrial sectors. Manufacturers benefit from high recyclability, advanced coatings, and strong branding potential. As sustainability and innovation shape the future, companies should explore tinplate solutions to meet evolving market needs and achieve their sustainable packaging goals.

- Superior strength and corrosion resistance

- High recyclability and support for sustainability

- Advanced coatings and excellent printability

- Versatile applications across industries

FAQ

What is a tinplate coil?

A tinplate coil consists of cold-rolled steel coated with pure tin on both sides. Manufacturers use tinplate coils to produce packaging for food, beverages, chemicals, and consumer goods. The tin layer provides corrosion resistance and an attractive finish.

Why do manufacturers prefer tinplate coils for packaging?

Manufacturers select tinplate coils for their durability, corrosion resistance, and recyclability. Tinplate coils meet international standards and offer customizable grades, tempers, and finishes. These features support safe, sustainable, and versatile packaging solutions.

How does tinplate coil improve food safety?

Tinplate coils provide a non-toxic, protective barrier that prevents contamination. The tin coating resists corrosion and maintains product integrity during storage and transport. Food-grade coatings comply with FDA and HACCP standards, ensuring consumer safety.

Can tinplate coils be recycled?

Tinplate coils are 100% recyclable. The steel and tin composition allows repeated recycling without quality loss. Many regions report tinplate recycling rates above 80%. This supports circular economy goals and reduces environmental impact.

What industries use tinplate coils?

Industries such as food and beverage, chemicals, cosmetics, and household goods rely on tinplate coils. These coils offer strong mechanical protection, moisture resistance, and decorative appeal for various packaging applications.

What customization options are available for tinplate coils?

Manufacturers can choose from multiple grades, tempers, thicknesses, and surface finishes. Options include bright, matte, stone, and silver finishes. Customization ensures optimal performance for specific packaging needs.

How do tinplate coils compare to aluminum and plastics?

Tinplate coils offer superior durability and corrosion resistance compared to aluminum and plastics. Tinplate packaging supports higher recyclability rates and provides better protection against moisture, light, and oxygen.

Tip: Tinplate coils deliver reliable performance and sustainability for modern packaging needs.

| Feature | Tinplate Coil | Aluminum | Plastics |

|---|---|---|---|

| Durability | High | Medium | Low |

| Recyclability | High | High | Low |

| Food Safety | Excellent | Good | Varies |