You face a fast-changing market for etp tinplate as 2025 approaches. Global demand continues to rise, with the market valued at over USD 5.3 billion in 2024 and expected to grow further. Understanding product specifications and supplier reliability helps you avoid costly errors. Technical documentation, application fit, and awareness of market trends give you a strong foundation for making confident sourcing decisions.

Key Takeaways

- Start your sourcing process by contacting Witop Tinplate early to get expert advice and accurate quotes.

- Choose ETP tinplate specifications like thickness, hardness, and surface finish based on your product needs for best performance.

- Witop Tinplate offers a wide range of steel grades, coatings, and finishes to match diverse packaging applications.

- Reliable quality assurance and detailed technical documentation help you avoid defects and ensure product safety.

- Evaluate suppliers based on experience, product range, and support to secure smooth procurement and timely delivery.

- Stay informed about global market trends and price changes to negotiate better deals and plan your budget.

- Consider sustainability and digital tools in your sourcing to meet environmental goals and improve efficiency.

- Use Witop Tinplate’s customization options to create unique packaging that stands out and fits your exact requirements.

Sourcing Process

Initial Steps

You need a clear plan before you start sourcing etp tinplate from Witop Tinplate. Taking the right first steps helps you avoid delays and confusion. Here is a recommended approach:

- Reach out to Witop Tinplate to start the conversation. Their team welcomes inquiries and offers free quotes.

- Share your specific requirements with their technical experts. You can discuss thickness, width, coating, and intended application.

- Request a detailed quote and consultation. This step gives you insight into pricing, product specifications, and supply options.

- Use Witop’s one-stop solution to streamline your procurement. Their team can help you match the right product to your packaging needs.

Tip: Early communication with Witop’s technical team ensures your order meets all technical and regulatory standards.

Requesting Quotes

You should request a formal quote once you define your needs. Witop Tinplate responds quickly to quote requests and provides detailed information. When you ask for a quote, include the following details:

- Desired thickness and width

- Steel grade and tin coating

- Quantity and packaging requirements

- Delivery location and timeline

Clear communication at this stage prevents misunderstandings. Witop’s technical documentation supports your decision-making. You can review product data sheets and test reports to confirm the material fits your application.

Order and Delivery

After you review and accept the quote, you can place your order. Witop Tinplate offers reliable lead times for different order types. The table below shows standard delivery times:

| Order Type | Standard Lead Time |

|---|---|

| OEM Orders | 25 days |

| Ready Goods | 30 days |

You should coordinate with Witop’s logistics team to schedule delivery. Timely delivery keeps your production on track. Always confirm shipping details and documentation before the order ships.

Note: Consistent follow-up with the supplier helps you manage timelines and avoid unexpected delays.

ETP Tinplate Overview

What Is ETP Tinplate

You encounter ETP tinplate in many industries because of its unique structure and properties. ETP stands for Electrolytic Tin Plate. Manufacturers produce it by coating a cold-reduced low-carbon steel sheet with a thin layer of pure tin using an electrolytic process. This process creates a material with a bright metallic luster and a smooth surface. You benefit from its excellent paintability and printability, which allow for high-quality branding and labeling.

ETP tinplate also offers strong formability, reliable strength, and impressive corrosion resistance. The tin coating, combined with passivation and a thin oil film, ensures food-safe handling and helps prevent rust. You can select from various temper grades, ranging from T1 (softest) to T5 (hardest), and choose different coating weights to match your packaging needs.

Applications

You find etp tinplate in a wide range of products across the globe. Its primary use lies in packaging, especially for food and beverages. You see it in cans for fruits, vegetables, meat, fish, carbonated drinks, juices, and beer.

The material’s corrosion resistance keeps food fresh and safe. You also use it for chemical packaging, aerosol spray cans, and closures like bottle caps and lids. In the cosmetics industry, etp tinplate protects products such as lip balm and moisturizers, offering both moisture resistance and an attractive appearance. Other applications include household utensils, electrical parts, oil filter components, and wire-shielding materials. Packaging accounts for about 70% of the global market, but you also see etp tinplate in electronics, construction, and engineering sectors. Its recyclability and environmental sustainability continue to drive demand.

Tip: ETP tinplate’s versatility makes it a top choice for industries that require both protection and visual appeal.

Benefits

You gain several advantages when you choose etp tinplate over alternative materials. Its excellent corrosion resistance protects contents from rust and extends shelf life. The material complies with food safety standards, making it suitable for direct contact with food and beverages.

You can shape it into intricate designs, thanks to its high formability and strength. ETP tinplate outperforms tin-free steel in both corrosion resistance and flexibility. You also benefit from its cost-effectiveness, especially in large-scale manufacturing. The material’s durability shields products from shocks and temperature changes during transport. ETP tinplate supports multiple openings and closings, which adds value for consumers. Its infinite recyclability helps you reduce waste and conserve resources, supporting circular economy goals. The lightweight nature of etp tinplate lowers transportation costs and emissions, while its high-quality printability enhances your brand’s visibility.

- Key benefits at a glance:

- Superior corrosion resistance and food safety

- High versatility and formability for custom packaging

- Cost-effective and durable

- Infinite recyclability and sustainability

- Lightweight and easy to transport

Specifications

Thickness and Width

When you source ETP tinplate, thickness and width are the first specifications you should review. These dimensions determine the material’s suitability for your packaging needs. Witop Tinplate offers a broad range of options to help you match your requirements:

| Parameter | Range |

|---|---|

| Thickness | 0.12 mm to 0.60 mm |

| Width | 20 mm to 1250 mm |

You can select thinner sheets for products that need complex shapes, such as food cans or aerosol containers. Thinner tinplate, typically between 0.15 mm and 0.48 mm, provides excellent formability. This makes it ideal for deep drawing and intricate designs. Thicker sheets, up to 0.60 mm, deliver greater strength and durability. These are best for large paint cans, chemical drums, or storage containers that require extra protection.

Width also plays a key role. Wider sheets allow you to produce larger containers or improve manufacturing efficiency by reducing waste. The following table summarizes how thickness and width impact application suitability:

| Parameter | Range/Values | Impact on Application |

|---|---|---|

| Thickness | 0.15 – 0.48 mm | Thinner sheets: better formability; thicker: more strength |

| Thickness Tolerance | ±0.01 mm | Ensures consistent quality |

| Width | 600 mm – 1200 mm | Enables various container sizes and efficient production |

| Width Tolerance | 0 / +3 mm | Maintains dimensional accuracy |

| Applications | Food cans, paint cans, aerosol cans, chemical cans | Tailored for diverse uses |

Tip: Always match thickness and width to your product’s forming process and strength requirements. This ensures optimal performance and cost efficiency.

Steel Base and Coating

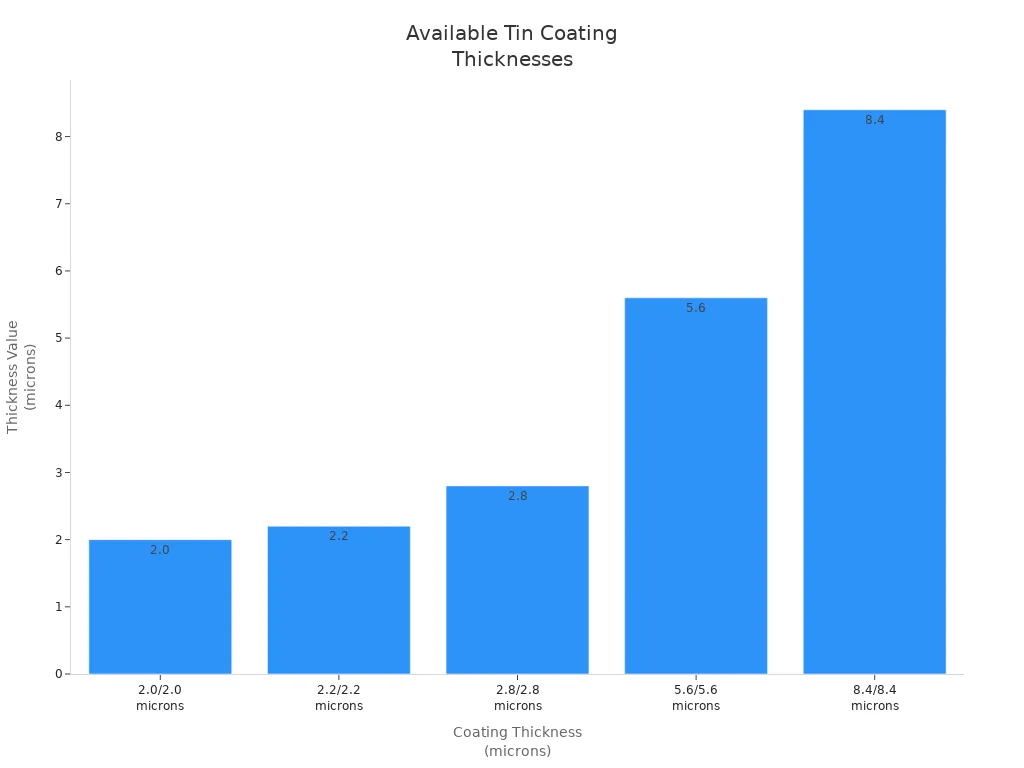

The steel base and tin coating define the core properties of ETP tinplate. Witop Tinplate uses high-quality cold-rolled steel bases, including MR, SPCC, SPHC, Q195, and S08AL grades. These steel types provide the foundation for mechanical strength and compatibility with tin coatings.

| Specification Category | Details |

|---|---|

| Steel Base Grades | MR, SPCC, SPHC, Q195, S08AL |

| Material Origin | BAO (BAOWU) Steel |

| Tin Coating Thickness | 2.0/2.0, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4 microns |

| Tin Weight | 1.1 g/m² to 8.4 g/m² |

The tin coating, applied by electroplating, acts as a barrier against corrosion. You benefit from superior rust protection, especially in food and beverage packaging. Thicker tin coatings, such as 5.6 or 8.4 microns, offer enhanced resistance for aggressive contents or longer shelf life. Thinner coatings, like 2.0 or 2.8 microns, suit less demanding environments and help reduce costs.

If the tin layer remains intact, your products stay protected from rust and oxidation. However, damage to the coating exposes the steel base, increasing the risk of corrosion. Choosing the right steel grade and coating thickness is critical for applications that demand high corrosion resistance, such as dairy cans, protein powder containers, and paint cans.

- ETP tinplate uses a cold-rolled steel base with a tin coating for corrosion protection.

- Electroplated tin offers better resistance than chromium coatings.

- The steel base affects strength and compatibility with the coating.

- High-quality coatings and steel grades are essential for food safety and durability.

Hardness

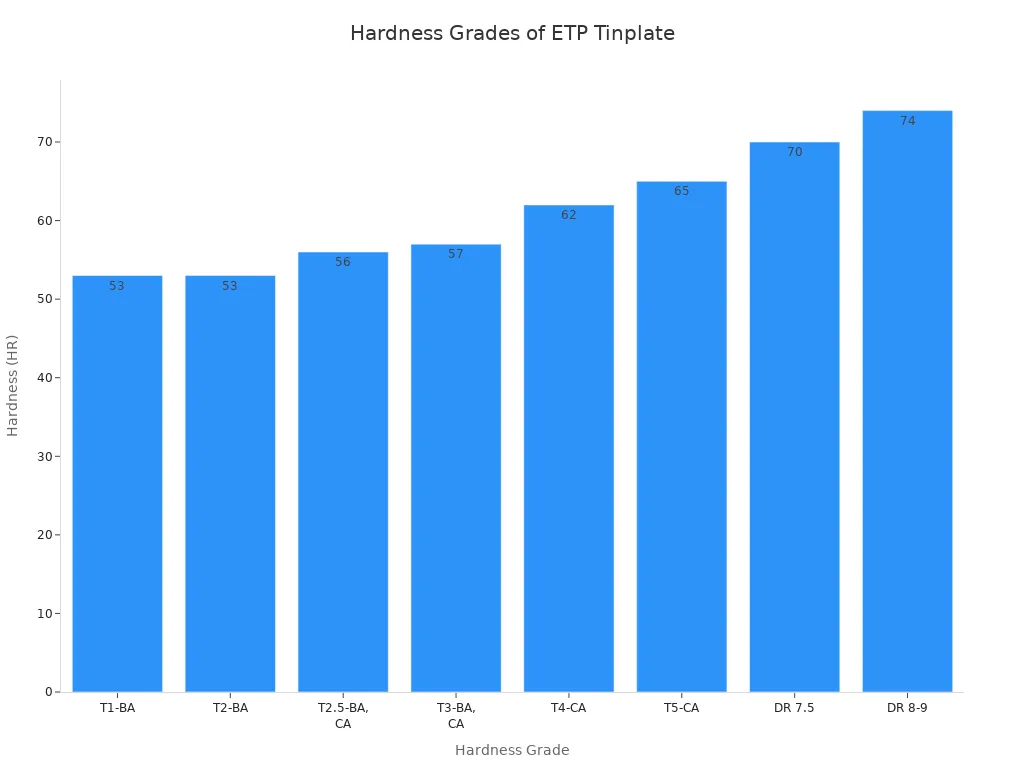

Hardness, also called temper, measures the strength and formability of ETP tinplate. You must select the right hardness grade to balance durability and ease of manufacturing. Witop Tinplate provides a full range of tempers, from T1 (softest) to DR9 (hardest).

| Hardness Grade | Hardness (HR) | Typical Uses in Packaging |

|---|---|---|

| T1-BA | Max 53 | Deep drawing parts: necks, nozzles, taps, bottoms for 5-gallon oil cans |

| T2-BA | 53 ± 4 | Small cans, fish cans, salted meat cans, moderate drawing |

| T2.5-BA, CA | 56 ± 4 | Crowns, cans needing moderate hardness and drawability |

| T3-BA, CA | 57 ± 4 | Bodies for large cans, 5-gallon oil cans, balanced hardness and formability |

| T4-CA | 62 ± 4 | Can bodies and bottoms, crown caps, higher strength |

| T5-CA | 65 ± 4 | Cans needing high hardness, strength, and good formability |

| DR 7.5 | 70 ± 4 | Small diameter cans requiring high strength |

| DR 8-9 | 73-76 ± 4 | Double reduced grades, greater stiffness, thinner material, same performance |

You use softer grades, like T1 or T2, for deep drawing and forming complex shapes. These grades work well for necks, nozzles, and small cans. Harder grades, such as T4, T5, or DR8, provide higher strength and stiffness. These are ideal for large containers, paint cans, or applications where you need thinner material without sacrificing performance.

Hardness directly affects how the tinplate performs during forming and filling. You must choose a temper that matches your production process and end-use. The right hardness ensures your packaging maintains its shape, resists dents, and protects contents throughout the supply chain.

Note: Always consult with Witop’s technical team to select the best hardness grade for your specific application. This helps you achieve the right balance of strength, formability, and cost.

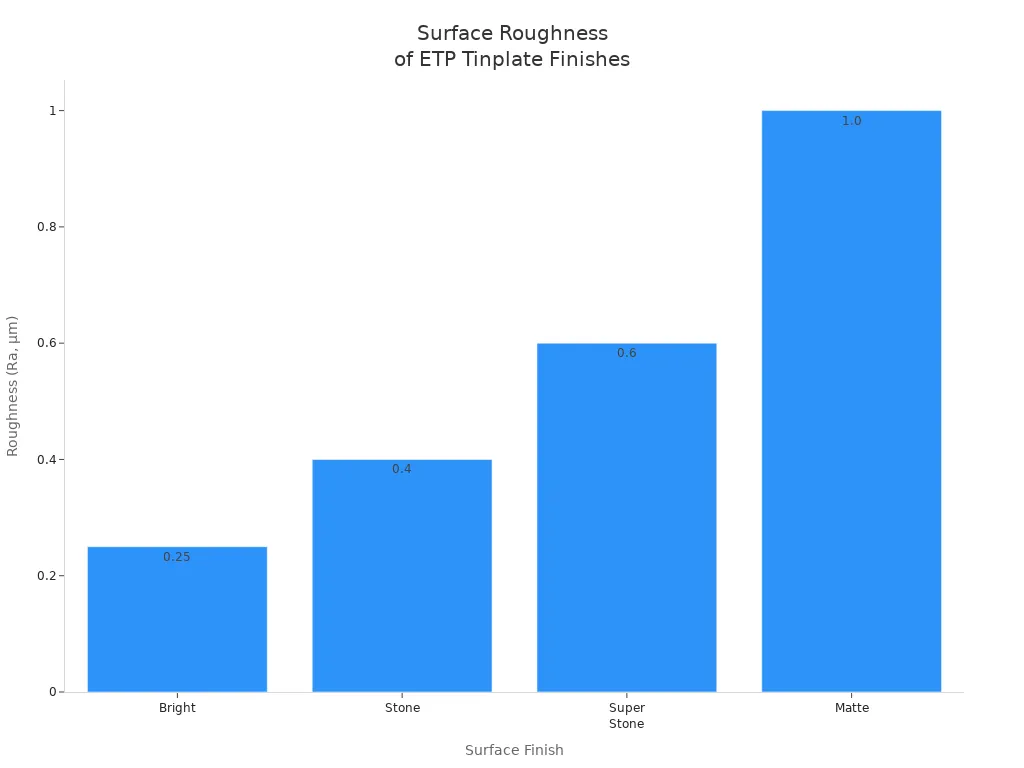

Surface Finish

When you select ETP tinplate, surface finish becomes a critical factor in both the appearance and performance of your packaging. Witop Tinplate provides a variety of surface finishes, each designed to meet specific application needs and visual standards.

You can choose from the following surface finishes:

- Bright

- Stone

- Matte

- Silver

Each finish offers unique characteristics that influence how your packaging looks and how well it accepts printing or lacquering. The right surface finish helps you achieve the desired brand image and ensures high-quality graphics on your cans or containers.

| Surface Finish | Surface Roughness (Ra) | Impact on Printability and Appearance |

|---|---|---|

| Bright | 0.25 | Smooth, glossy surface ideal for vibrant printing and general use. |

| Stone | 0.40 | Subtle stone marks mask scratches, improving visual quality. |

| Super Stone | 0.60 | Heavier texture affects both print finish and tactile feel. |

| Matte | 1.00 | Dull finish, often used for crowns and DI cans; printability differs due to rougher surface. |

| Silver (Satin) | Rough dull finish | Used for artistic cans, offers a unique matte look and distinct print effect. |

A smooth and even surface, such as the Bright finish, allows inks and lacquers to adhere better. You get sharper images and more vibrant colors, which is essential for food cans, beverage packaging, and any product where shelf appeal matters. Stone and Super Stone finishes introduce subtle or pronounced textures. These textures help hide scratches from can-making or handling, maintaining a clean look throughout the supply chain.

Matte and Silver finishes provide a duller, less reflective surface. You often use these for specialty packaging, crowns, or artistic cans where a unique visual effect is required. However, rougher surfaces can reduce print vibrancy and may require adjustments in your printing process.

Tip: Always match the surface finish to your product’s branding and technical requirements. A high-gloss Bright finish works best for premium food cans, while a Matte or Silver finish can set your product apart in niche markets.

Surface finish not only affects appearance but also plays a role in corrosion resistance and ease of manufacturing. By choosing the right finish from Witop Tinplate, you ensure your packaging stands out and performs reliably in its intended application.

Choosing ETP Tinplate

Matching Requirements

You need to match your packaging needs with the right ETP tinplate specifications. This step ensures your products perform well and meet industry standards. When you select tinplate, focus on these key factors:

- Surface finish: Choose from stone, bright, or silver finishes. Each finish affects the appearance and printability of your packaging.

- Grade: Select from grades like T1, T2, T3, T4, T5, MR, SPHC, and SPCC. Each grade offers different strength and formability.

- Thickness: Pick a thickness between 0.15mm and 0.8mm. Thinner tinplate works well for food cans, while thicker options suit paint cans or welding uses.

- Hardness: Match the hardness level (such as T3, T57, T61, T65) to your forming process and product durability needs.

- Intended use: Identify if you need food-grade tinplate, which often uses a 0.15-0.5mm stone finish for food cans.

Tip: Always review your product’s requirements before finalizing your order. The right match improves performance and reduces waste.

Custom Orders

You may need custom solutions for unique packaging or branding. Witop Tinplate supports your business with flexible customization options:

- Printed customization: Add your logo, brand colors, or product information directly onto the tinplate.

- Specification customization: Adjust thickness, width, coating, and finish to fit your exact needs.

- Product range: Order ETP tinplate as coils or sheets, tailored to your production process.

These options help you create packaging that stands out on the shelf and meets your technical requirements. Custom orders also allow you to respond quickly to market changes or new product launches.

Note: Discuss your customization needs with Witop’s technical team early in the process. This ensures smooth production and on-time delivery.

Quality Assurance

You want confidence in every batch of ETP tinplate you receive. Witop Tinplate uses a strict quality assurance process to deliver consistent results. Their production steps include:

- Pickling removes iron oxide and inspects for surface defects.

- Cold rolling controls friction and temperature for material integrity.

- Degreasing cleans the steel to prevent stains and ensure quality.

- Annealing softens the steel and creates the right grain structure.

- Temper rolling restores processability and relieves work hardening.

- Smoothing improves plate shape and achieves the correct hardness.

- Tin coating pre-treatment ensures a clean surface for electroplating.

- Packaging protects the tinplate during transport and storage.

This process gives you reliable, high-quality tinplate for your packaging lines. You reduce the risk of defects and keep your production running smoothly.

Callout: Quality assurance at every stage helps you meet safety and performance standards in your industry.

Supplier Evaluation

Experience

You want a supplier with a proven track record. Witop Tinplate brings years of experience in the tinplate industry. Their team understands the challenges you face in sourcing ETP tinplate. They have supplied products to clients in food, chemical, and industrial sectors worldwide. This experience helps them anticipate your needs and offer practical solutions.

You benefit from their knowledge of international standards and regulations. Witop Tinplate stays updated on the latest industry trends. Their expertise ensures you receive products that meet both technical and safety requirements. You can trust their recommendations when you need to select the right grade or finish for your application.

Tip: Choose a supplier with a strong history in your industry. This reduces risk and increases your confidence in every order.

Product Range

You need flexibility when sourcing tinplate. Witop Tinplate offers a wide product range to match your requirements. You can select from various thicknesses, widths, and surface finishes. Their catalog includes options for food cans, paint cans, aerosol containers, and more.

The table below highlights some of the available choices:

| Product Type | Thickness Range | Surface Finish Options | Application Examples |

|---|---|---|---|

| ETP Tinplate Coil | 0.12–0.60 mm | Bright, Stone, Matte | Food cans, chemical drums |

| ETP Tinplate Sheet | 0.15–0.50 mm | Silver, Super Stone | Lids, artistic packaging |

You can request custom specifications for unique projects. Witop Tinplate supports both large-scale and small-batch orders. This flexibility helps you adapt to changing market demands and new product launches.

Support

You expect more than just a product from your supplier. Witop Tinplate provides comprehensive support throughout your sourcing process. Their team offers technical guidance to help you select the best tinplate for your needs. You can request free samples before placing a large order. This allows you to test the material and ensure it fits your application.

Witop Tinplate’s after-sales service includes:

- Technical support for product selection and troubleshooting

- Free samples for product evaluation

- Customization services, including printed designs and specification adjustments

You receive prompt responses to your inquiries. Their team works closely with you to resolve any issues quickly. This level of support helps you maintain smooth production and meet your deadlines.

Note: Strong supplier support reduces downtime and helps you deliver quality products to your customers.

Documentation

Technical Data

You need accurate technical data to make informed sourcing decisions. Witop Tinplate provides detailed product specifications for every order. You receive information on thickness, width, steel grade, tin coating weight, hardness, and surface finish. This data helps you verify that the material matches your requirements before production begins. You can request technical data sheets that include mechanical properties, chemical composition, and dimensional tolerances. These documents support your quality control process and help you meet industry standards.

Tip: Always review the technical data sheet before approving your order. This step ensures you avoid costly mistakes and maintain consistent product quality.

Testing Results

You want confidence that your tinplate meets international quality standards. Witop Tinplate uses advanced testing equipment and follows recognized standards to verify product quality. The table below shows the main testing standards and equipment used:

| Testing Standards | Testing Equipment |

|---|---|

| GB/T 2520-2000 | PMI Test |

| JIS G3303-2002 | Component Analysis |

| DIN EN 10203-1991 | Size Inspection |

You benefit from a comprehensive quality assurance process. Witop Tinplate tests each batch for thickness, hardness, coating weight, and surface finish. The company also works with third-party inspection agencies such as SGS, BV, CE, COC, and AI. These organizations provide independent verification of product quality. As an ISO verified manufacturer, Witop Tinplate maintains strict control over every production step.

- Testing standards include BS EN 10202, DIN EN 10203, GB/T 2520, and JIS G3303.

- Third-party inspections ensure unbiased quality checks.

- Flexible payment options and stock availability support your procurement needs.

- You can track production and transport for full transparency.

Application Fit

You need to confirm that the tinplate you order fits your intended application. Witop Tinplate helps you match product specifications to your packaging needs. You can discuss your requirements with their technical team and receive guidance on the best grade, thickness, and finish. The company provides application-specific documentation, including test results and compliance certificates. This information helps you meet regulatory requirements and customer expectations.

Note: Request application fit documentation for every new project. This step helps you avoid compatibility issues and ensures your packaging performs as expected.

Global Sourcing

Market Options

You have a wide range of choices when sourcing ETP tinplate globally in 2025. Each region offers unique advantages, from established supply chains to emerging growth opportunities. The table below highlights the main regions, key countries, leading manufacturers, and market characteristics:

| Region | Key Countries / Areas | Leading Companies / Manufacturers | Market Characteristics and Trends |

|---|---|---|---|

| Europe | Germany, UK, France, Italy, Russia, Spain | SteelPro Solutions, Global CanTech, European Steelworks, Metal Packaging Innovations, Horizon Metal Solutions | Mature market, strong demand for sustainable packaging, innovation focus, capacity expansions, regional dominance. |

| North America | United States, Canada, Mexico | Eastern Tinplate Corp, Integrated Metals Inc, Pacific Steel & Tin | Mature market, established food processing industry, focus on sustainability and innovation. |

| Asia-Pacific | China, Japan, Korea, India, Australia, Southeast Asia | Asia Tinplate Group, NextGen Packaging, Prime Steel Group | High growth potential, expanding middle class, increasing canned food demand, rapid urbanization. |

| South America | Brazil, Argentina, Colombia | Consolidated Metals, Apex Tinplate | Emerging markets, growing industrial bases, increasing adoption of modern packaging solutions. |

| Middle East & Africa | South Africa, UAE, Saudi Arabia | Regal Steelworks, Quantum Tin | Developing markets, expanding supply networks, focus on sustainable packaging adoption. |

You can source from mature markets like Europe and North America, where suppliers focus on sustainability and innovation. Asia-Pacific offers rapid growth and expanding capacity, especially in China and India. South America and the Middle East & Africa present new opportunities as their industries modernize and demand for packaging rises.

Tip: Evaluate regional strengths and supplier capabilities to match your sourcing strategy with your business goals.

Price Trends

You need to monitor price trends closely when sourcing ETP tinplate. In 2025, prices reflect both global supply and regional demand. Mature markets in North America and Europe show stable pricing, driven by established supply chains and steady demand for sustainable packaging. You may see moderate price increases due to stricter environmental regulations and higher production costs.

Asia-Pacific stands out for competitive pricing, thanks to large-scale production and growing domestic consumption. Rapid urbanization and rising incomes in countries like China and India boost demand, but also encourage local manufacturers to expand capacity. This helps keep prices attractive for buyers.

Emerging regions such as South America and the Middle East & Africa may experience more price volatility. These markets are still developing their supply chains and often rely on imports. You should factor in currency fluctuations, shipping costs, and local tariffs when planning your procurement budget.

- Key factors influencing ETP tinplate prices in 2025:

- Raw material costs (steel and tin)

- Regional supply-demand balance

- Environmental regulations

- Transportation and logistics expenses

Note: Regularly review market reports and supplier updates to stay ahead of price changes and secure the best value.

Import Data

You benefit from understanding import data when planning your sourcing strategy. In 2025, global trade in ETP tinplate continues to grow, with Asia-Pacific leading in both production and exports. China remains the largest exporter, supplying tinplate to markets in Europe, North America, and beyond. Japan and Korea also play key roles as major exporters.

Europe and North America import significant volumes to meet their packaging industry needs. These regions prioritize quality, sustainability, and compliance with food safety standards. South America and the Middle East & Africa increase their imports as local demand rises and domestic production expands.

Leading global tinplate suppliers include:

- Ball Corporation

- Crown Holdings, Inc.

- Ardagh Group S.A.

- Silgan Holdings Inc.

- Can-Pack S.A.

- CPMC Holdings Limited

- Toyo Seikan Group Holdings, Ltd.

- HUBER Packaging Group GmbH

- Kingcan Holdings Limited

- Massilly Holding S.A.S.

- Sonoco Products Company

- Amcor Limited

- Rexam PLC

- Envases Universales Group

- Hindustan Tin Works Ltd.

You should analyze import data to identify reliable suppliers, assess lead times, and anticipate potential supply chain disruptions. Tracking import volumes and trade flows helps you make informed decisions and maintain a steady supply of ETP tinplate for your business.

Callout: Use import statistics and supplier performance data to strengthen your sourcing strategy and reduce risk.

Trends 2025

Competitive Pricing

You will see more suppliers competing on price in 2025. Global production capacity continues to expand, especially in Asia-Pacific. This trend gives you more options and better leverage during negotiations. You can expect suppliers to offer volume discounts, flexible payment terms, and bundled services. Many buyers now use real-time price tracking tools to compare offers and spot market shifts.

Tip: Always request updated quotes before placing an order. Market prices can change quickly, especially with fluctuations in steel and tin costs.

You can use the following strategies to secure the best pricing:

- Compare quotes from at least three suppliers.

- Monitor raw material price indexes.

- Negotiate for long-term contracts to lock in rates.

- Ask about seasonal promotions or loyalty discounts.

A simple table can help you track and compare supplier offers:

| Supplier | Price per Ton | Lead Time | Payment Terms | Extras |

|---|---|---|---|---|

| Witop Tinplate | $X,XXX | 25 days | 30% deposit | Free samples |

| Supplier B | $X,XXX | 30 days | 20% deposit | Custom printing |

| Supplier C | $X,XXX | 28 days | 25% deposit | Fast shipping |

Sustainability

You face growing pressure to choose sustainable materials. Many brands now require eco-friendly packaging to meet consumer and regulatory demands. ETP tinplate stands out because you can recycle it infinitely without losing quality. In 2025, you will see more suppliers investing in green production methods and transparent supply chains.

You should look for these sustainability features:

- High recycled content in steel base

- Tin sourced from responsible suppliers

- Certifications like ISO 14001 or REACH compliance

- Reduced use of hazardous chemicals

Note: Choosing sustainable tinplate helps you meet environmental goals and improves your brand image.

You can also ask suppliers for environmental impact reports. These documents show energy use, emissions, and recycling rates. Many buyers now include sustainability criteria in their supplier scorecards.

Digital Tools

You gain a competitive edge by using digital tools in your sourcing process. In 2025, more buyers rely on online platforms, AI-driven analytics, and digital documentation. These tools help you track orders, compare specifications, and manage compliance with ease.

Key digital trends include:

- Online supplier portals for instant quotes and order tracking

- AI-powered price forecasting and demand planning

- Digital quality certificates and test reports

- Automated alerts for shipment status and market changes

Callout: Embracing digital tools streamlines your workflow and reduces errors.

You can also use mobile apps to approve orders or review technical data on the go. Digital transformation in procurement saves you time and helps you make faster, data-driven decisions.

You now have a clear roadmap for sourcing from Witop Tinplate. Review your technical requirements, evaluate supplier experience, and stay informed about market shifts. Reliable documentation and strong support help you avoid costly mistakes. Take the next step—reach out for a quote or consultation. Your proactive approach will keep your supply chain strong and your business competitive.

FAQ

What is the minimum order quantity for ETP tinplate?

You can place orders starting from 25 metric tons. This quantity helps you optimize shipping costs and ensures consistent product quality.

How long does delivery take after I place an order?

You usually receive OEM orders within 25 days. Ready goods ship in about 30 days. Witop Tinplate’s logistics team coordinates with you for timely delivery.

Can I request custom sizes or finishes?

Yes, you can customize thickness, width, coating, and surface finish. Witop Tinplate’s technical team works with you to match your exact requirements.

Does Witop Tinplate provide quality certifications?

You receive ISO, SGS, and other third-party certifications with your order. These documents confirm that your tinplate meets international quality and safety standards.

How do I get technical support or samples?

You can contact Witop Tinplate’s support team for technical guidance. Free samples are available for product evaluation before you place a large order.

What payment terms does Witop Tinplate offer?

You can choose flexible payment options, such as a 30% deposit with the balance due before shipment. The team will discuss terms that fit your needs.

How does Witop Tinplate ensure product quality?

Witop Tinplate uses strict quality checks at every production stage. You receive detailed test reports and can request third-party inspections for added assurance.

Can I track my order status online?

Yes, you can track your order and shipment status through Witop Tinplate’s digital portal. You receive updates at every key stage of the process.